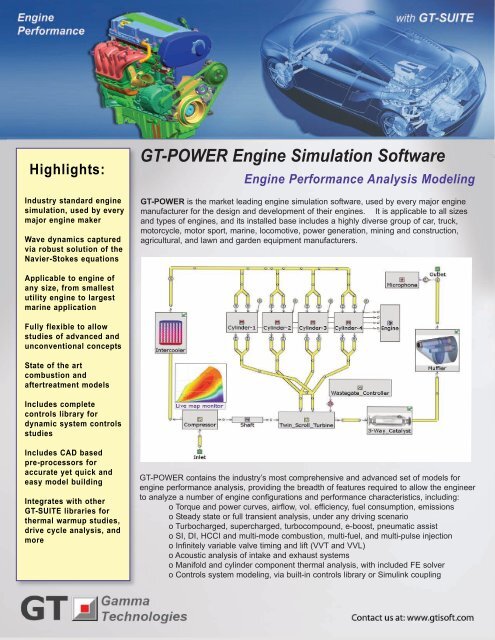

This paper highlights an efficient way to investigate the transient engine behaviour using an original numerical approach based on the coupling between IFP-ENGINE, a 1D engine simulation tool, and IFP-C3D, a 3D combustion code. IFP-C3D is employed to extend or replace the experimental combustion maps used in IFP-ENGINE in the form of Wiebe's law. 1D engine modelling and re-calculation of the baseline engine configuration. ABOUT SIMULATION. Today’s powerful multi-dimensional simulation platforms allow the setup of all kinds of virtual engines to perform analysis work, setting up of complete new power train concepts, and optimisation of existing engines in advance of any cost. EngineSim: ( 455KB) EngineSim is a simulator that models the design and testing of jet engines. The program works in two modes: Design Mode or Tunnel Test Mode. In the Design Mode, you can change design variables including the flight conditions, the engine size, the inlet performance, the turbo machinery compressor and turbine performance, the combustors or burner performance, or the nozzle. Lotus Engine Simulation. The engine model, designed with LESoft, is shown in Figure 7. The engine model consists of the cylinder (“CYL1” element), and intake and exhaust networks each of which is designed using three elements representing connector, port, and valve.

Releases

3.3.1, May 2020

3.3.0, March 2019

3.2.4, January 2018

3.2.2, February 2017

3.1.0, January 2016

3.0.5, October 2014

3.0.4, June 2014

3.0, November 2013

2.4, April 2012

2.2, September 2011

2.0, February 2010

1.4.1, June 2009

1.0.1, January 2008

User Cases

Applications

Modelling rocket and satellite propulsion systems

- Simulation of ground, spacecraft and launch vehicle propulsion systems under transient and steady conditions

- Propulsion system with two-fluid mixtures under gas, liquid and two-phase flow regimes for a wide database of working

- Studies of water hammer, pressure drop, priming processes, etc. in fluid networks

- Hydraulic and pneumatic systems, equipment and combustors, with heat transfer and controls loops coupled together

- Transient simulation of liquid, solid and hybrid rocket engines

- Simulation of ramjet engines

- Orbital and attitude motion of satellites.

- Performance analysis and design of space engines

- Electrical propulsion systems

- Modeling of combustors, heat-exchangers, turbo-machinery, pumps, tanks, etc.

Description

European Space Propulsion System Simulation (ESPSS) is an European Space Agency (ESA) toolkit for modelling rocket and satellite propulsion systems. EAI is the official distributor after prior approval from ESA and the primary developer of the libraries.

It consists of a set of libraries based on the EcosimPro simulation environment, incorporating an open (reusable) object-oriented programming language, powerful solvers and a friendly Graphical User Interface.

The ESPSS toolkit provides components and functions for the simulation of launch vehicle and spacecraft propulsion systems able to work under transient and steady conditions. ESPSS also includes a complete database of fluids to be used as propellants, pressurizing fluids or other applications.

The palettes of components allow the user to graphically build complex models quickly and to add new components to the library.

ESPSS provides a state-of-the-art tool in propulsion systems analysis successfully validated with the help of analytical solutions (1D Pipe & Combustor models), experiments entailing priming cases, two-phase tank filling processes, the Ariane 5 ESC-A upper stage, etc.

Today, EcosimPro/ESPSS is used widely by many aerospace companies for modelling sophisticated rocket and satellite propulsion systems. It is also being used to model new concepts of propulsion systems that could represent significant milestones in future propulsion systems, including hybrid propulsion and electric propulsion.

ESPSS Features

ESPSS software can be used for complex fluid systems definition under transient and steady conditions, mission analysis, impact studies, investigation of anomalies and optimization, among others. It comprises:

- Standard fluid database for a wide range of simulations

- Multidisciplinary libraries able to simulate different effects in the same model:

- Fluid networks with detailed simulation of transient aspects due to inertia (water-hammer), heat exchange (radiators) or control processes.

- Pressurization systems including priming processes, tank behaviour, heat transfer, mechanical or electronic pressure regulators, etc.

- Combustion processes calculating chemical equilibrium of a mixture in transient and non-adiabatic conditions taking into account vaporization and reaction time.

- Liquid, hybrid and solid rocket engines with one or more combustion chambers including turbo-machinery and two-phase cooling systems.

- Simplified study of movement and attitude of satellites, orbital transfers and orbit control coupled to their propulsion system.

- First operational version of electric propulsion systems based on correlations.

- A standalone library with the necessary components for the calculation of steady performances of liquid rocket engine cycles under design and off-design conditions.

- Optimization Module for design and test fitting.

- Easy-to-share models between EcosimPro users and also exportable as black boxes to be simulated independently.

- Multiple possibilities of interaction with external engineering software like Matlab/Simulink, Excel, etc.

Videos

Startup and Shutdown of a Staged Liquid Rocket Engine

Engine Simulation Game

When a liquid rocket engine starts up or shuts down, a complex transient process takes place. This example reproduces the architecture and performances of an engine similar to the Main Engine of the Space Shuttle in such conditions, showing the evolution of pressures, temperatures or mass fluxes through different components.

The model consists of two fuel supply lines, high and low pressure turbo-machinery for each line, a pre-chamber to move the turbines, the main combustion chamber and the nozzle extension, the fluid network and the thermal network including two cooling circuits and the heat transfer among the fluid, the walls and the ambient.

An important number of input data of the model like geometry, valve opening laws, working fluids or initialization of dynamic variables are set in the components before simulating the experiment. The following plots show the evolution of pressures and temperatures in the three combustion chambers and the mass flows through their injectors, the temperatures in each section of the cooling circuits and the pressures and rotational speed of the turbo-machinery:

Priming of a Piping Network

This model represents a complex piping network, which is usually part of a bigger system. The purpose of this case is to show how a priming process is simulated in ESPSS, highlighting some of the most representative variables. The model is composed only of fluid elements, such as pipes, junctions, volumes and valves.

Depending on the input data selected (geometry of the system, initial conditions imposed, etc.) different responses of the model can be obtained (mass flows, pressure peaks, temperature evolution, etc.). It can be observed that the priming process reproduces the pressure peaks in different points as the fluid fills the pipes. The following plots show the evolution of pressures, temperatures, mass flows, void fraction and non-condensable mass fraction in different points of the system:

Oxygen Pressurization System

One of the most important subsystems for space propulsion applications is the fuel storage and pressurization system. The following model shows the LOX pressurization system of the Ariane 5 by means of electro‐valves. The Tank (containing LOX, He and GOX vapors as pressuring gas) is simulated with a complex component capturing vaporization, fluid temperature distribution, etc.

The pressurization system consists of a set of three latch valves (PPO subsystem): the first one is normally open; the second opens when the tank pressure drops below a predefined threshold (variable in time) and closes when this pressure exceeds another threshold; the third one is normally closed. The PPO collector is pressurized with Helium coming from a Sphere at very low temperature, which is heated when passing through the reheater RHE placed inside the turbine exhaust lines (“GazChaud” flow). The reheater subsystem includes passive temperature control, thanks to the bypass lines.

At times up to ‐300s, the tank remains in boiling pressurization because no gas is injected inside; a small outlet vapor flow exiting the tank through the VPSO valve compensates any possible heat leaks. The system pressurizes the tank from time ‐245 to ‐10 seconds. The Relay control component is responsible to switch the valve between +‐0.15 bar around the set point imposed by “Pset”. Before the start up of the engine at -300 seconds, the EAPO subsystem pressurizes the Tank to P=5 bar. Then, at TIME = ‐10 this system is switched off and the PPO subsystem is activated.

The following plots show the evolution of pressures, temperatures, heat fluxes, liquid level in the tank and mass flows:

2013-09-08Download Citation

1d Engine Simulation Software Simulation

SAE MOBILUS

Subscribers can view annotate, and download all of SAE's content. Learn More »

Computational Development of a Dual Pre-Chamber Engine Concept for Lean Burn Combustion

2016-01-2242

TECHNICAL PAPERLarge Eddy Simulation of an Ignition Front in a Heavy Duty Partially Premixed Combustion Engine

2019-24-0010

TECHNICAL PAPER

TECHNICAL PAPER Unsteady Three-Dimensional Computational Experiments of the Single-Point Auto-Ignition Engine Based on Semispherical Supermulti-Jets Colliding with Pulse for Automobiles

Jet Engine Simulation Software

2014-01-2641